LSZH Fiber Optic Cables Tutorial

Since the 1970s, the wire and cable industry has been using low-smoke, low-halogen materials in a number of applications. The objective was to create a wire and cable jacketing that was not only flame retardant but also did not generate dense, obscuring smoke and toxic or corrosive gases. Several notable fires over the years (such as the King's Cross Fire that killed 32 people in London's underground subway in 1987) increased the awareness of the role that wire and cable jacketing plays in a fire and contributed to a greater adoption of Low-Smoke Zero-Halogen (LSZH) cables.

With an increase in the amount of cable found in residential, commercial and industrial applications in recent years, there is a greater fuel load in the event of a fire. Wire and cable manufacturers responded by developing materials that had a high resistance to fire while maintaining performance. Low-smoke, zero-halogen compounds proved to be a key materials group that delivered enhanced fire protection performance. Today, LSZH cables are being used in applications beyond the traditional transit, shipboard, military and other confined-space applications. This tutorial is provided to help you learn more about the LSZH fiber optic cables.

What is LSZH Fiber Optic Cable?

LSZH Fiber Optic Cable is a kind of fiber optic cable of which the jacket and insulation material are made of special LSZH materials. When these cables come in contact with a flame very little smoke is produced making this product ideal for applications where many people are confined in a certain place (office buildings, train stations, airports, etc.). While a fire may be very harmful in a building, the smoke can cause more damage to people trying to locate exits and inhalation of smoke or gases.

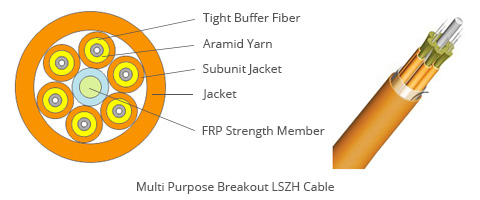

|

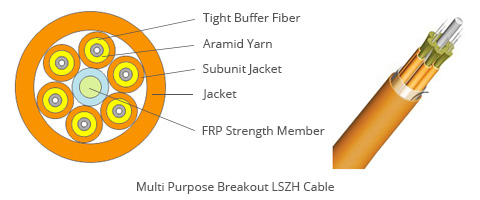

|

Fiber optic cable insulation and jacket made from LSZH materials are free of halogenated materials like Fluorine (F), Chlorine (Cl), Bromine (Br), Iodine (I) and Astatine (At), which are reported to be capable of being transformed into toxic and corrosive matter during combustion or decompositions in landfills.

The most prominent characteristic of LSZH fiber optic cable is safety. LSZH fiber optic cables are used in public spaces like train and subway stations, airports, hospitals, boats and commercial buildings, where toxic fumes would present a danger in the event of a fire. Similarly, low-smoke property is also helpful. More people in fires die from smoke inhalation than any other cause. Using LSZH fiber optic cables which release low smoke and zero halogenated materials in these places would be really important to the safty of people.

Applications of LSZH Fiber Optic Cables

There is no doubt that the amount of fiber optic cables installed in buildings has been increasing as data communication proliferated. Central office telecommunication facilities were some of the first places that LSZH cables became common due to the large relative fuel load represented by wire and cable.

Public Spaces like train stations, hospitals, school, high buidings and commercial centers where the pretection of people and equipment from toxic and corrosive gases is critical should apply LSZH fiber optic cable for the safty of people.

Data Centers contain large amounts of cables, and are usually enclosed spaces with cooling systems that can potentially disperse combustion byproducts through a large area. In industrial facilities, the relative fuel load of cables will not be at the same level. Other materials burning may also contribute greater amounts of dangerous gases that outweigh the effect of the cables. There have been notable fires where cables burning contributed to corrosion (the Hinsdale Central Office fire is a famous example), but in some instances, better fire response techniques could have prevented this damage.

Nuclear Industry is another area where LSZH cables have been and will be used in the future. Major cable manufacturers have been producing LSZH cables for nuclear facilities since the early 1990s. The expected construction of new nuclear plants in the U.S. in coming years will almost certainly involve some LSZH cable.

One of the most important things to understand about LSZH fiber optic cable is that no two products are the same and that there are many factors that will define the suitability of the final product to its application. In fact, research done by a major pulling lubricant supplier tested 27 LSZH compounds and found a huge variation in physical properties. So even using material that meets the base requirements of one of the many specifications available may not result in the best material for the application. Understanding the goals, results and limits of these tests are key to finding the right product. In any case, the trend to consider environmental concerns with a greater weight relative to performance has increased and it can be generally stated that there is an enlarging market for fiber optic cables that can be demonstrated to be environmentally friendly.

Conclusion

When selecting or designing a fiber optic cable for any application, the operating enviroments where the fiber optic cable will be used, whether extreme or not, must be considered along with availability, performance, and price, among other things. And when the safety of humans and the enviroment is a consideration, along with high-performance and capability, then LSZH fiber optic cables are what you must specify.

Warm Tips: When choosing LSZH fiber optic cables, factors such as the environment and price should be considered. An environmental factor such as the temperature of the installation could reduce the flexibility of the cable. Will the application be in an open area or confined? Will other flammable material be present? LSZH fiber optic cables also tend to be higher in cost.